The Vehicle Technologies Office (VTO) is supporting research and development (R&D) to improve motors in hybrid and plug-in electric vehicles, with a particular focus on reducing the use of rare earth materials currently used for permanent magnet-based motors.

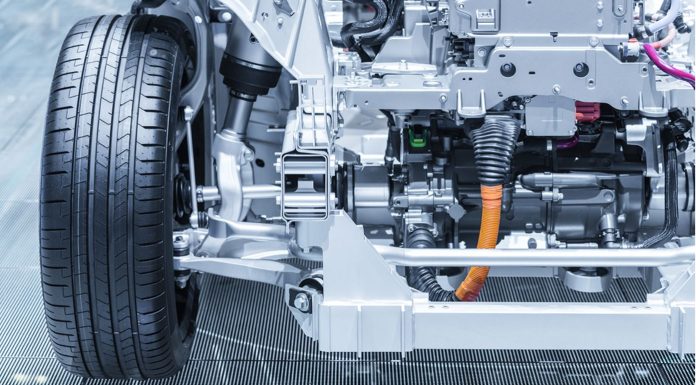

In an electric drive system, an electric motor converts the stored electrical energy in a battery to mechanical energy. Electric motors consist of a rotor (the moving part of the motor) and a stator (the stationary part of the motor). A permanent magnet motor includes a rotor containing a series of magnets and a current-carrying stator (typically taking the form of an iron ring), separated by an air gap. There are three types of electric motors that can be used in hybrid or plug-in electric vehicle traction drive systems.

- Internal permanent magnet (IPM) motors have high power density and maintain high efficiency over a high percentage of their operating range. Almost all hybrid and plug-in electric vehicles use rare earth permanent magnets in their traction motors. Because of the high costs of magnets and rotor fabrication, these motors are relatively expensive. Other challenges to using IPM motors include the limited availability and high cost of rare earth magnetic materials. Despite the challenges, the automotive industry anticipates continuing to use IPM motors in the majority of electric drive vehicles over the next decade.

- Induction motors have high starting torque and offer high reliability. However, their power density and overall efficiency are lower than that of IPM motors. They are widely available and common in various industries today, including some production vehicles. Because this motor technology is mature, it is unlikely research could achieve additional improvements in efficiency, cost, weight, and volume for competitive future electric vehicles.

- Switched reluctance motors offer a lower-cost option that can be easy to manufacture. They also have a rugged structure that can tolerate high temperatures and speeds. However, they produce more noise and vibration than comparable motor designs, which is a major challenge for use in vehicles. Also, switched reluctance motors are less efficient than other motor types and require additional sensors and complex motor controllers that increase the overall cost of the electric drive system.