It is admirable that the Indian government has upheld and strengthened its dedication to fostering a gradual shift to a transportation system dominated by electric vehicles (EV). The research estimates that this industry emits 142 million tonnes of carbon dioxide (CO2) each year, of which 123 million are attributable to the road transport industry alone. Electric mobility offers a workable solution to this problem and helps to maintain the balance between the country’s energy demand, energy storage, and environmental sustainability. Additionally, e-mobility provides a comprehensive solution to numerous problems pertaining to human health, the environment, and vehicle affordability.

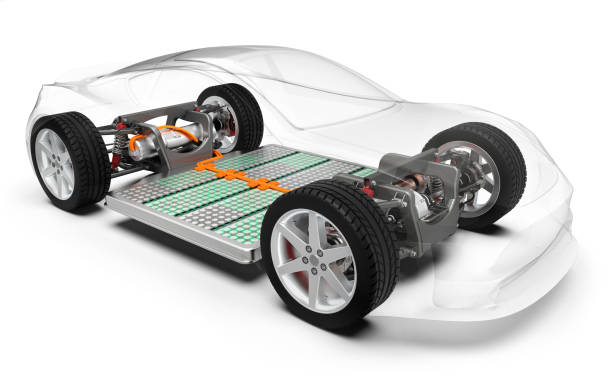

The Indian government is pressuring the sector to produce the components domestically in order to create a domestic supply chain for electric vehicles under the ‘Atmanirbhar Bharat’, a self-reliant India’, scheme. Due to their high energy density, low self-discharge, quick charging, and lightweight construction, lithium-ion batteries are the industry standard for EV transportation. The majority of the lithium is controlled by China, which presents a significant challenge for the Indian EV market.

Impact of FAME

The Indian government needs to raise private investment in addition to giving subsidies for EVs in order to increase EV adoption in India and establish the country as a value chain participant. The nation has already started to achieve this through the FAME (Faster Adoption and Manufacturing of Electric Vehicles) initiative. The program’s goals were to promote EV adoption, quicken domestic production, and offer manufacturers incentives to make EVs in India.

However, purchase prices continue to be an issue in the price-sensitive Indian market, and this is where localization has a big impact. In determining the future of EVs in the country, price is a key factor. To encourage companies to start producing EV batteries domestically, the government recently launched a production-linked incentive program. In order to effectively repurpose the valuable metals in used automobile batteries, policy coordination, and design for end-of-life EVs may also be introduced during this process. This is especially true with respect to urban mining and EV battery recycling.

National Research funders

National research funders have also underlined the need of figuring out more efficient ways to manufacture and recycle batteries. Because it is still typically more affordable to mine metals than to recycle them, one important goal is to develop technologies to recover valuable metals in an economically viable manner that can compete with newly mined ones. Some potential solutions include cutting back on the use of metals, enhancing recycling, and increasing production.

The sector ultimately needs long-term acceptance to support local innovation. The government’s admirable and forward-thinking PLI scheme is a positive step. NITI Aayog is aiming to encourage that innovation and bring manufacturing capability to the country because there may be a demand for EVs but you may not always be able to provide it at the right price without securing the supply chain.

With the right incentives and legal framework, India can overcome considerable barriers to EV battery recycling and seize the lead over the next ten years.