As automobile gas mileage standards continue to increase (according to the Environmental Protection Agency, up to 40 miles per gallon by 2026), the challenge for automotive audio designers is how to provide an immersive audio experience while simultaneously reducing vehicle weight and improving overall efficiency.

If you design automotive external amplifiers, you can refresh your audio system architectures to enhance the user experience by increasing output power, leveraging higher-impedance speakers and implementing Class-H control in your system.

Supporting higher output power using a higher supply voltage and higher output current

In addition to original equipment manufacturer (OEM) demands to reduce vehicle weight, consumers are seeking premium audio performance that creates an immersive experience in their vehicles. To develop systems that create a such an experience, designers like to integrate more powerful subwoofers that can continuously pump out window-rattling bass and provide a greater dynamic range (the difference between the quietest and loudest sounds measured in decibels) of sound replication.

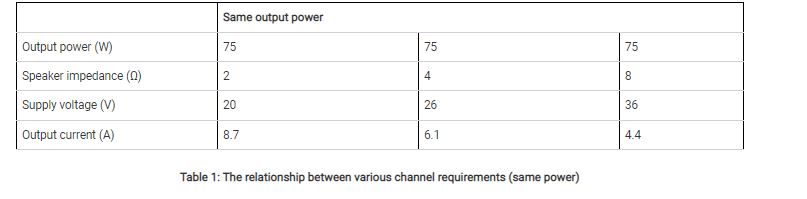

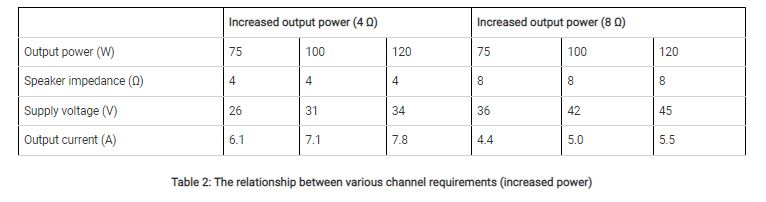

To increase the dynamic range along with higher output power, consider boosting the input supply voltage. Table 1 shows the supply-voltage and output-current values needed to maintain 75 W of output power as the speaker impedance increases.

Table 2 shows a correlation between increased power demand and the supply voltage/output current. In this case, the demand for higher output power – to 100 W and then 120 W – requires both increased supply voltage and increased output current, for the same speaker impedance.

Why higher-impedance speakers can save overall weight

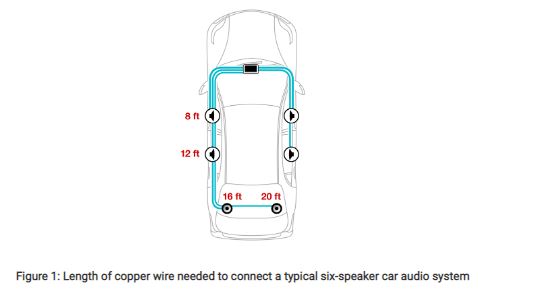

As shown in Table 1, a benefit of using higher-impedance speakers is that the output current drops significantly while maintaining the same output power. And the relative size (diameter) of the copper wire can be reduced as you lower the required output current. For instance, a smaller-diameter wire can support an 8-Ω speaker versus a 4-Ω speaker or a 2-Ω speaker at the same output power – helping to reduce audio cable weight.

In the simplified installation shown in Figure 1, which depicts a six-speaker car audio system supporting a mid-range speaker in each car door and two additional speakers in the rear, you would need approximately 76 feet of copper wire to connect all speakers.

A positive effect of increasing the speaker impedance is that it provides an opportunity to reduce the cable diameter. When you multiply this by the shear amount of cabling typically used to interconnect all speakers to the audio external amplifier, you can really lower the overall weight of your audio system.

Implementing Class-H control to optimize system efficiency and further save weight

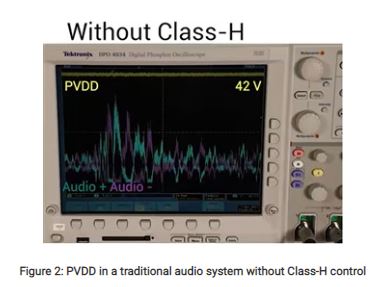

In a traditional audio system, the power-supply solution typically sets the audio amplifier’s supply voltage (labeled PVDD) for all speakers at the highest required voltage in order to deliver the peak power required by the audio load, as shown in Figure 2.

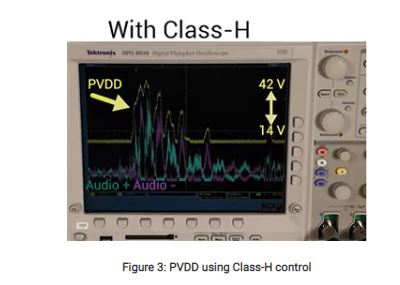

Implementing a technique called Class-H control (using an automotive Class-D audio amplifier, such as the TAS6584-Q1) makes it possible to optimize the PVDD voltage supplied to the amplifier (see Figure 3) and dynamically track the envelope of the audio waveform. Class-H control significantly improves the efficiency of the audio design and saves power that would have been otherwise dissipated if the PVDD voltage was fixed at 42 V.

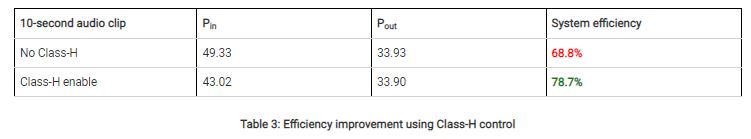

To further illustrate the impact on efficiency that Class-H control can provide, let’s look at the data in Table 3. Using the TAS6584-Q1-based Automotive Class-H Audio and Tracking Power-Supply Reference Design, which enables the toggling of Class-H control on or off, Table 3 compares the power input (Pin) into the system vs. the power dissipated (Pout). With Class-H control, the system efficiency gain is nearly 10% between the boost supply controller and audio amplifier.

Improving the efficiency also lowers the overall power losses of the external amplifier, as shown in Figure 4.

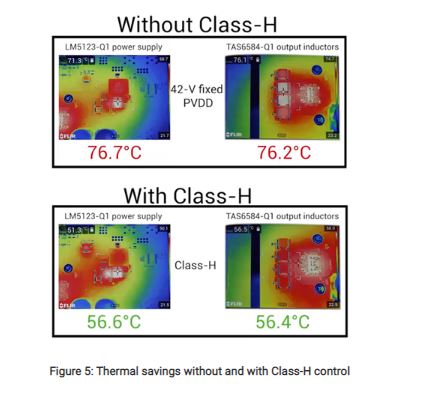

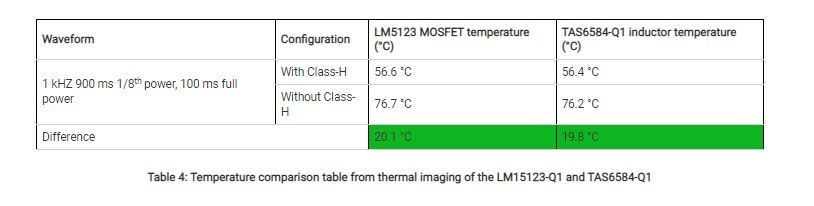

To further illustrate this point, let’s look at thermal camera images of the TAS6584-Q1 audio amplifier and LM5123-Q1 boost controller power supply with Class-H control on and off and compare their heat signatures. Figure 5 shows how the implementation of Class-H control significantly lowers the total thermal heat load.

As in Figure 5, the improved efficiency of Class-H control (through the reduction in power losses) helps drive a lower thermal load, enabling the selection of a smaller heat sink to dissipate the internal heat.

Conclusion

I hope that I effectively showed how leveraging higher-impedance speakers and implementing Class-H control can help you to develop an even lighter-weight audio system; and how external amplifier weight savings can translate into one of the following benefits: longer driving distances, the ability to include a greater number of speaker channels in an overall audio design, and increase the overall average output power per channel for an existing number of car speakers.

Courtsey: Texas Instruments