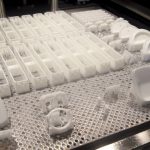

SLA 3D PRINTING

We have “India’s largest prototyping machine”, This is SLA process (Stereolithography) belongs to additive manufacturing technologies known as vat photopolymerization, commonly known as resin 3D printing. These machines are all built around the same principle, using a light source a laser or a projector to cure liquid resin into

We have “India’s largest prototyping machine”, This is SLA process (Stereolithography) belongs to additive manufacturing technologies known as vat photopolymerization, commonly known as resin 3D printing. These machines are all built around the same principle, using a light source a laser or a projector to cure liquid resin into hardened plastic. The main physical differentiation lies in the arrangement of the core components, such as the light source, the build platform, and the resin tank. SLA 3D printers use light-reactive thermoset materials called “resin.” When SLA resins are exposed to certain wavelengths of light, short molecular chains join together, polymerizing monomers and oligomers into solidified rigid or flexible geometries.

hardened plastic. The main physical differentiation lies in the arrangement of the core components, such as the light source, the build platform, and the resin tank. SLA 3D printers use light-reactive thermoset materials called “resin.” When SLA resins are exposed to certain wavelengths of light, short molecular chains join together, polymerizing monomers and oligomers into solidified rigid or flexible geometries.

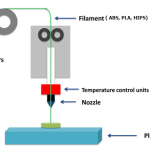

FDM 3D PRINTING

FDM 3D PRINTING

Fused Deposition Modeling (FDM) Technology works with specialized 3D printers and production-grade thermoplastics to build strong, durable and dimensionally stable parts with the best accuracy and repeatability of 3D printing technology. Ranging from inexpensive prototyping materials like ABS and PLA, up to engineering and high-performance 3D printing materials like ABS, PLA, Nylon, Hips.

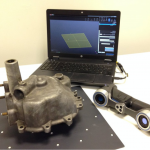

3DSCANNING & INSPECTION

A very common challenge in the world of engineering and product design is 3DScanning & Inspection a physical product for which you do not have a CAD file. Using a 3D scanner that will capture the complex geometric characteristics of a given part is a great way to develop a CAD file when one is not available. Creating or sourcing

A very common challenge in the world of engineering and product design is 3DScanning & Inspection a physical product for which you do not have a CAD file. Using a 3D scanner that will capture the complex geometric characteristics of a given part is a great way to develop a CAD file when one is not available. Creating or sourcing high-quality CAD files early on in the 3DScanning & Inspection process can greatly improve the results of the project by minimizing wasted time and guesswork based on inaccurate data. Time and time again RA Global has found that our 3DScanning & Inspection solutions have minimized CAD creation time and led to more successful 3DScanning & Inspection.

high-quality CAD files early on in the 3DScanning & Inspection process can greatly improve the results of the project by minimizing wasted time and guesswork based on inaccurate data. Time and time again RA Global has found that our 3DScanning & Inspection solutions have minimized CAD creation time and led to more successful 3DScanning & Inspection.

Courtesy: NextGen3DTech