Courtesy: Keysight Technologies

Growing demands for electric vehicles, underpinned by incentives for car buyers to switch to electric transportation and policies driving zero-emission goals, are fueling the need for electric vehicle (EV) charging stations. The global EV charging station market will increase from 2.35 million units in 2022 to 14.6 million units by 2027, at a compound annual growth rate of 44.1%.

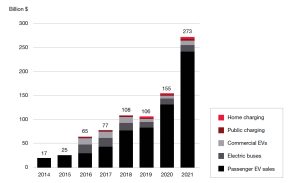

Electric passenger car sales far outstrip investments in public charging infrastructure, leaving ample room for growth in the EV supply equipment (EVSE) market.

The global trend in increased EVSE investment will help address range anxiety, the fear of running out of power before reaching the next charging station.

Electrified transport investment by category

Figure 1. Global electrified transport investment (Source: BloombergNEF)

Charging Stations Must Comply with EMC Standards

EVSE suppliers must tackle new technology challenges, including safety, performance, and interoperability between EVs and EVSE.

With expectations of faster and high-power charging comes the need to ensure safety and performance across an ever-increasing range of car models and EVSE vendors. A key area is ensuring electromagnetic compatibility (EMC) of the EVSE, not just with the vehicles it will charge but also with the plethora of electronic devices that rule our modern lives.

With more charging stations sprouting up, especially near residential areas and schools, EMC standards are evolving to protect both the public and the industry.

For EVSE makers, complying with these standards helps ensure product safety, performance, and reliability while building market confidence and brand reputation.

Before taking a deeper dive into the implications of electromagnetic interference (EMI) in the EV charging environment and why EMC conformance testing is so important, let’s briefly recap these two abbreviations:

- EMI: electromagnetic disturbances that degrade the performance of electronic or electrical equipment

- EMC: the ability of electrical and electronic systems and devices to operate in their intended electromagnetic environment without unacceptable degradation from electromagnetic interference

Why is EMC testing so important?

While in use, a charging station can produce radiated emissions caused by electromagnetic waves. It can also produce conducted emissions as the voltage or current flows through the power cable.

These electromagnetic interferences can disrupt the proper functioning of other electromechanical devices and wireless communications and may pose health risks to people. With the convergence of connected autonomous vehicles on the electric car platform, testing charging stations against any interference with onboard safety and communication systems is vital.

Researchers from the Technical University of Munich in Germany studied EV and EVSE electromagnetic fields and their impact on the pacemakers implanted in cardiac patients. The strongest electromagnetic field was along the charging cable during high current charging (116.5 μT). The field strength in the EV cabin was lower, at 2.1 to 3.6 μT.

The researchers found no change in the functioning of the pacemakers. But as EV and EVSE technology advances, the researchers said patients should be cautious around Level 2 (240 V) and Level 3 (400 V) charging stations, which use strong electric current.

Juggling multiple EMC standards

EVSE manufacturers must meet EMC regulatory requirements and certifications before going to market.

For instance, the European IEC 61000 EMC standard defines limits intended to provide reasonable protection against harmful interference. This directive addresses EMI issues for EV charging infrastructure products.

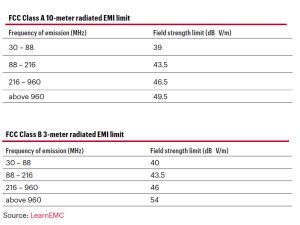

In the United States, the Federal Communications Commission (FCC) regulates EMC compliance. Class A limits cover commercial, business, and industrial environments. Class B, the more stringent category, covers EVSE in residential areas (see Table 1).

Table 1. FCC Class A and Class B radiated EMI limits

In Canada, the ICES-003 Section 5 standards require EV charging station providers operating in areas exposed to the general public to have Class B compliance. If a charging station does not have Class B certification, it must display a warning label cautioning users that magnetic fields around it can be problematic. Such a warning does not help an EVSE supplier gain market confidence.

Other key charging and EMC norms and standards include the following:

- IEC 61851-21: This EMC product standard specifies the limits of emission and immunity (the minimum test levels) for electric road vehicle charging systems.

- IEC / CISPR 11, EN 55011: The CISPR 11 standard covers emissions requirements related to radio-frequency disturbances in the 9 kHz to 400 GHz frequency range.

- TL 81000: This covers the electromagnetic compatibility of electronic components for motor vehicles.

Measuring Up to EMC Compliance

Ensuring that EVSEs meet safety and performance standards boils down to having comprehensive compliance test processes and reliable test and measurement equipment. These essentials for measuring the causes and impacts of electrical noise allow engineers to find ways to define, debug, and circumvent the EMI causes and effects.

In addition to testing the EVSE’s circuitry, manufacturers must thoroughly test user interfaces against both conducted and radiated emissions. Those interfaces include touch screens, displays, and wireless communications such as those used for contactless payment.

To meet these evolving conformance standards and regulations, EVSE manufacturers need to factor in their test capacity and ability to handle increasing test complexity (see Figure 2) while planning their design, development, and production cycles.

Comprehensive EMC testing covers the following:

- radiated emissions test

- conducted emissions test

- radiated immunity test

- wireless test

- environmental test

- safety test

Re-Creating the Charging Station in the Lab

In today’s competitive e-mobility market, EVSE manufacturers must adapt quickly to test a wide range of electric vehicles and ensure that their charging products conform to different standards around the world. In many cases, the EVSE manufacturer does not have access to detailed information about how the EV manufacturer implemented its controller or if it complied with the published standards.

For this reason, a holistic compliance test requires a “synthetic” setup, which can emulate the real-world environment of a charging station, operate within given specifications, and provide appropriate means of defect detection and analysis. This “real-world emulation” test environment provides further advantages:

- A real electric car is unnecessary in the test lab. The emulator can assume the specifications of different EV models.

- Charging duration is unrestricted, as the testing uses an electronic load instead of a battery, which would have limited capacity.

- Moreover, tests can be fully automated, which is particularly useful for recurring test sequences and large numbers of units, such as in end-of-line testing.

A key consideration for EMC testing in this emulated environment is whether the test equipment is properly shielded to offer the unbiased measurements needed for EMC compliance and homologation tests.

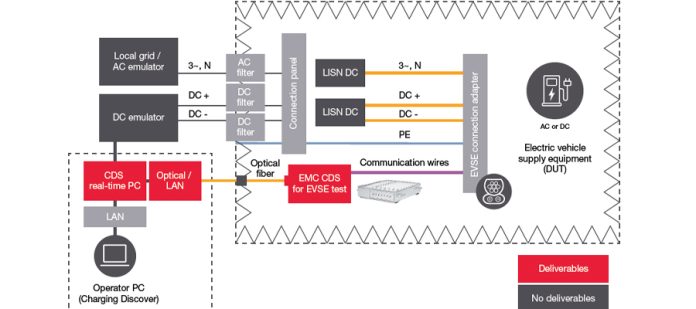

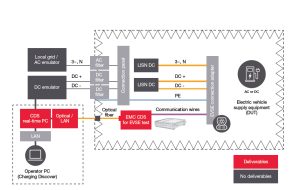

The EMC test architecture illustrated in Figure 3 shows an EMC-optimized charging test system, the Keysight SL1040A-EM2 Scienlab Charging Discovery System (CDS) — EMC Series for EVSE Test. In the illustration, the CDS acts as an electric car to test the EV supply equipment.

Both the test system and the EVSE — in this case, the device under test (DUT) — operate inside an anechoic chamber for EMC immunity and emission tests (conducted or radiated) of EV charging infrastructure during AC or DC charging.

The special EMC shielded design and built-in low-noise components help reduce emulator emissions to a minimal level. This process enables EMC testing of EVSEs under real charging conditions without environmental interferences. Furthermore, since this test system is immune to external electromagnetic fields, it can sit close to the DUT during immunity tests.

Keysight’s SL1040A Scienlab Charging Discovery System — EMC Series (Figure 4) supports AC and DC charging communication standards.

It supports AC charging mode according to the following:

- IEC 61851-1 (PWM)

- SAE J1772 (PWM)

- ISO 15118

- GB/T 18487.1 (PWM)

It supports DC fast charging mode according to the following:

- DIN SPEC 70121

- ISO 15118

- GB / T 27930

- CHAdeMO

In addition, the solution offers these benefits:

- reliable, interoperable emulation of the EV charging communication controller with SL1040A-EMC, or of the EVSE charging communication controller with SL1040A-EM2

- easy configuration of charging protocol and operating point through Windows Control software or optionally via customer automation software (using the CDS remote interface)

- real-time capable control PC with high system performance and low dead times

- portable shielded “galvanized metal” case with grounding contact springs

Note: IPC typically sits outside the EMC chamber.

EVSE Testing Outlook

Demand for EVSE testing is likely to grow in the coming years, buoyed by market drivers such as fast and high-power charging and the convergence of connected automated driving features on the e-mobility platform. While new conformance standards and regulations may pose challenges for EVSE manufacturers, they open up opportunities for test houses offering EMC testing and certification services.

This collaborative approach is a win-win for the industry, allowing EVSE manufacturers to focus on developing and deploying safe, reliable charging infrastructure as part of the bigger picture of a zero-carbon-footprint transportation future.