Osamah Ahmad, Co-authored by Kevin Stauder, Texas Instruments

With the continued worldwide growth of hybrid electric vehicles (HEVs) and electric vehicles (EVs), now more than ever, automotive developers are innovating to stay ahead of the game. While differentiating HEV/EV powertrain systems has traditionally been a key focus area, market leaders now cannot afford to neglect differentiating their HEV/EV thermal management or heating, ventilation and air-conditioning (HVAC) systems. Thermal management systems consume the second most power in HEV/EVs (only behind powertrain systems) – directly impacting drive range.

For decades, the internal combustion engine (ICE) has run vehicles and their HVAC systems. In HEV/EVs, the size or even the absence of an ICE requires the introduction of two additional components that play a role in an HVAC system:

- A brushless-DC (BLDC) motor to rotate the AC compressor, instead of the engine doing so.

- A positive temperature coefficient (PTC) heater (or alternatively, a heat pump) to heat the coolant, rather than the engine heating the coolant. In the case of heat pumps, battery thermal management moves heat from the battery to the cabin. Integration of the heat pump ultimately results in lower weight, longer drive times and lower cost. See Figure 1.

Figure 1: The heating and cooling system in an HEV and EV

In this article, we’ll overview the design challenges associated with these electronic HVAC applications, and discuss how real-time control performance, scalability and cost can help address those challenges.

Reliable real-time control performance

High startup torque, high efficiency, low audible noise and low electromagnetic interference (EMI) are the primary features in market-leading e-compressor systems.

Let’s review the most important elements of HVAC performance, and why it’s important to consider them:

- High startup torque: Systems with high inertia such as e-compressors require high startup torque in order to run the compressor motor at the preferred speed as quickly as possible, ultimately increasing the end-user experience with the HVAC system.

- High efficiency: Other than a HEV/EV powertrain system, an e-compressor system consumes the most power in EV/HEVs: around 5 kW. As a result, any power savings through efficiency results in a longer driving range, which is a concern for HEV/EV developers and consumers.

- Low audible noise and low EMI: In ICE vehicles, the engine is already audible such that any noise coming from the HVAC system is minuscule by comparison. But EVs and HEVs are susceptible to audible noise that stands out in an otherwise quiet vehicle without engines. HEVs and EVs are also susceptible to EMI from the BLDC motor and electronics needed for the e-compressor. The e-compressor components in HEVs and EVs should not add any type of noise that would disturb the existing system or the consumer driving experience.

- While the quality of e-compressor products are directly affected by the system’s real-time control performance, traditional PTC heaters can fully function without it, and designers lean primarily on cost to differentiate these products. A PTC heater measures and controls the current flowing through the system (with a single resistor), which ultimately controls the in-cabin temperature.

- Heat pumps do indeed rely on strong real-time control performance, given the integration of multiple motors on a single system. System and microcontroller (MCU) architectures play an important role in enabling efficient and cost-effective control of an integrated heat-pump system.

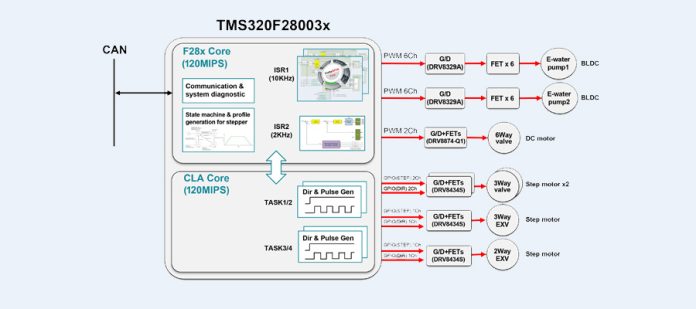

The block diagram in Figure 2 shows how the architecture and peripherals of TI’s C2000 real-time MCUs can enable a heat-pump system through multi-motor control.

Figure 2: A heat-pump system controlled by a C2000 real-time MCU

Scalability

Given evolving trends and varying requirements from automotive original equipment manufacturers worldwide, the ability to leverage a compatible platform to scale across different application requirements is a priority. A platform-based approach to an automotive HVAC compressor, PTC heater and heat-pump design helps significantly reduce time to development and development costs. For MCUs specifically, a wide range of options on package type, pin count, flash memory, temperature, functional safety (Automotive Safety Integrity Level B), cybersecurity, communication interfaces and cost are vital to enabling a scalable platform for automotive HVAC designers.

Cost

System bill of materials, development resources and time to market are all significant costs for automotive HVAC developers. Cost-effective components (including the MCU), the ability to leverage a scalable platform and reference designs help address these concerns.

TI’s High-Voltage EV/HEV E-Compressor Motor Control Reference Design is a high-voltage, 5-kW reference design built for EV/HEV e-compressor applications that’s controlled by the C2000 TMS320F2800157-Q1 real-time MCU. This reference design showcases solutions to some HEV/EV e-compressor design challenges in performance, scalability and cost. See this reference design in action here: EV HVAC eCompressor motor control

Conclusion

HEV and EV adoption builds over the coming decades, so will the use of electronic solutions for HVAC control. The automotive HVAC subsystems in these vehicles require components that bring forth design challenges such as reliable real-time control, scalability and cost. With the help of C2000 real-time MCUs and reference solutions, you can smoothly navigate the move from ICE to HEV and EV HVAC systems.