As the automotive industry embraces electric mobility, taking weight out of the car has become a fundamental goal of automakers. As per a recent report by the Aluminum Association and conducted by FEV North America, aluminum offers significant cost savings to automakers as net-zero priorities drive vehicle development, particularly in high-volume programs.

The researchers noted that the light-weighting cost dynamics in battery electric vehicles (BEVs) are significantly different than those for ICE vehicles.

The decision to lightweight BEVs is much more complicated than simply trading battery cost for light-weighting cost. Adding batteries adds weight to BEVs, reducing their performance and requiring increases in the size and cost of the powertrain and suspension systems to maintain performance. Adding batteries takes up additional space in the vehicle, and this additional space may be limited or unavailable.

The cost and storage density of automotive battery systems are continuously improving and the light-weighting cost dynamics for BEVs of the future will be significantly different than those for BEVs of today. Finally, fuel economy and emissions regulations are often assessed on the manufacturer’s whole fleet, meaning that equivalent fuel economy improvements made on BEVs could have a profound impact on the need to improve fuel economy and emissions in other ICE vehicles in the manufacturer’s fleet.

The research includes an analysis of three vehicle segments—city vehicle, family crossover, and pickup truck—and finds aluminum is an economically attractive mass reduction tool to improve performance and efficiency in BEVs.

According to Blake Zuidema, director of technical development for Novelis and Aluminum Transportation Group (ATG), aluminum is the fastest-growing automotive material, and as the industry makes a seismic shift to electrification, decision-makers need a clear view of how aluminum’s role evolves alongside this transition.

“The new data quantifies and reaffirms that as battery electric vehicles become more widely available, reducing mass through the application of aluminum, at optimized levels, offers significant net cost savings,” Zuidema added.

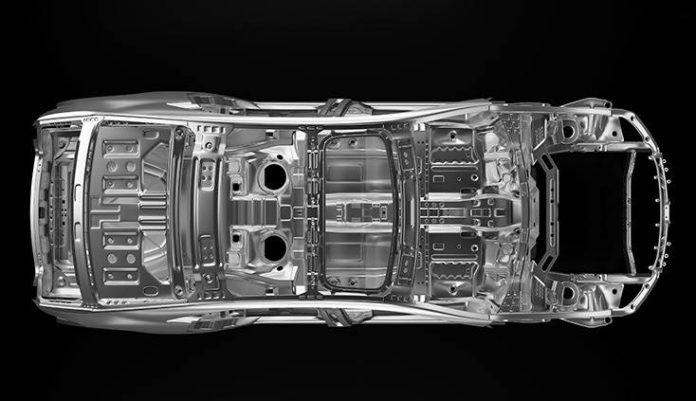

The study finds BEVs contain greater aluminum content than their internal combustion engine (ICE) counterparts with larger, more performance-oriented BEVs containing the largest percentage of aluminum compared to smaller models.

The study also suggests that the attractiveness of aluminum will actually increase over the next decade. In all three vehicles and in both the 2025 and 2030 time horizons, vehicle cost decreased as aluminum share initially increased, indicating that increasing aluminum content beyond today’s levels will further decrease BEV cost both today and in the future. This trend is driven largely by increases in consumer demands for a greater range over time.

The results of this study indicate that today’s battery electric vehicles contain more aluminum than their internal combustion engine counterparts of similar size and mission, that aluminum content increases with increasing battery electric vehicle size and performance expectations, and that aluminum light-weighting will continue to remain economically attractive as expected as battery and electric powertrain cost and efficiency improve over the current decade.